|

[Previous Page]

CHAPTER V.

THE LOCOMOTIVE ENGINE—GEORGE STEPHENSON BEGINS ITS IMPROVEMENT.

THE rapid

increase in the coal-trade of the Tyne about the beginning of the

present century had the effect of stimulating the ingenuity of

mechanics, and encouraging them to devise improved methods of

transporting the coal from the pits to the shipping-places. From our

introductory chapter, it will have been observed that the

improvements which had thus far been effected were confined almost

entirely to the road. The railway wagons still continued to be drawn

by horses. By improving and flattening the tram-way, considerable

economy in horse-power had been secured; but, unless some more

effective method of mechanical traction could be devised, it was

clear that railway improvement had almost reached its limits.

Notwithstanding Trevithick's comparatively successful experiment

with the first railway locomotive on the Merthyr Tydvil tram-road in

1804, described in a former chapter, he seems to have taken no

farther steps to bring his invention into notice. He was probably

discouraged by the breakage of the cast-iron plates, of which the

road was formed, which were crushed under the load of his engine,

and could not induce the owners of the line to relay it with better

materials so as to give his locomotive a fair trial.

An imaginary difficulty, also, seems to have tended, among other

obstacles, to prevent the adoption of the locomotive, viz., the idea

that, if a heavy weight were placed behind the engine, the "grip" or

"bite" of its smooth wheels upon the equally smooth iron rail must

necessarily be so slight that they would whirl round upon it, and,

consequently, that the machine would not make any progress. [p.152] Hence Trevithick, in his patent, provided that the periphery of the

driving-wheels should be made rough by the projection of bolts or

cross-grooves, so that the adhesion of the wheels to the road might

thereby be better secured.

Trevithick himself does not seem to have erected another engine, but

we gather from the evidence given by Mr. Bastrick in the committee

on the Liverpool and Manchester Bill in 1825, that ten or twelve

years before that time he had made an engine for Trevithick after

his patent, and that the engine was exhibited in London. "A

circular railroad was laid down," said Mr. Bastrick, and it was

stated that this engine was to run against a horse, and that which

went a sufficient number of miles was to win. It is not known what

afterward became of this engine. [Ed.—see

p.86.]

There were, however, at a much earlier period, several wealthy and

enterprising men, both in Yorkshire and Northumberland, who were

willing to give the locomotive a fair trial; and had Trevithick but

possessed the requisite tenacity of purpose—had he not been too soon

discouraged by partially successful experiments—he might have risen

to both fame and fortune, not only as the inventor of the

locomotive, but as the practical introducer of railway locomotion.

One of Trevithick's early friends and admirers was Mr. Blackett, of

Wylam. The Wylam wagon-way is one of the oldest in the north of

England. Down to the year 1807 it was formed of wooden spars or

rails, laid down between the colliery at Wylam—where old Robert

Stephenson worked—and the village of Lemington, some four miles down

the Tyne, where the coals were loaded into keels or barges, and

floated down past Newcastle, to be shipped for London. Each

chaldron-wagon had a man in charge of it, and was originally drawn

by one horse. The rate at which the wagons were hauled was so slow

that only two journeys were performed by each man and horse in one

day, and three on the day following. This primitive wagon-way

passed, as before stated, close in front of the cottage in which

George Stephenson was born, and one of the earliest sights which met

his infant eyes was this wooden tram-road worked by horses.

Mr. Blackett was the first colliery owner in the North who took an active

interest in the locomotive. He had witnessed the first performances

of Trevithick's steam-carriage in London, and was so taken with the

idea of its application to railway locomotion that he resolved to

have an engine erected after the new patent for use upon his

tram-way at Wylam. He accordingly obtained from Trevithick, in

October, 1804, a plan of his engine, provided with

"friction-wheels," and employed Mr. John Whinfield, of Pipewellgate,

Gateshead, to construct it at his foundry there. The engine was made

under the superintendence of one John Steele, [p.154]

an ingenious mechanic, who had been in Wales, and worked under

Trevithick in fitting the engine at Pen-y-darran. When the Gateshead

locomotive was finished, a temporary way was laid down in the works,

on which it was run backward and forward many times. For some reason

or other, however—it is said because the engine was too light for

drawing the coal-trains—it never left the works, but was dismounted

from the wheels, and set to blow the cupola of the foundry, in which

service it long continued to be employed.

Several years elapsed before Mr. Blackett took any farther steps to

carry out his idea. The final abandonment of Trevithick's locomotive

at Pen-y-darran perhaps contributed to deter him from proceeding

farther; but he had the Wylam wooden tram-way taken up in 1808, and

a plate-way of cast iron laid down instead—a single line furnished

with sidings to enable the laden wagons to pass the empty ones. The

new iron road proved so much smoother than the old wooden one, that

a single horse, instead of drawing one, was enabled to draw two, or

even three laden wagons.

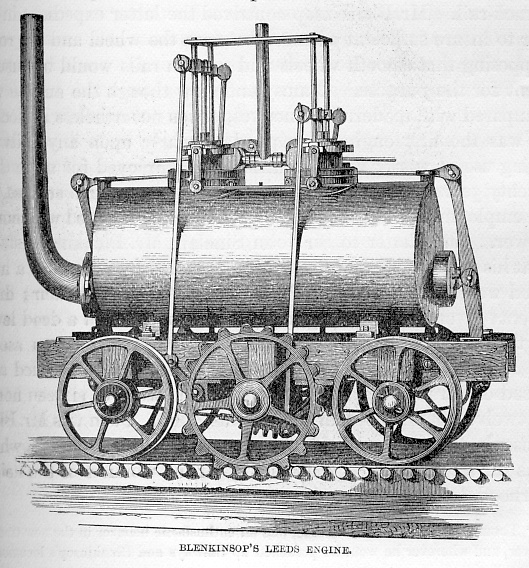

Although the locomotive seemed about to be lost sight of, it was not

forgotten. In 1811, Mr. Blenkinsop, the manager of the Middleton

Collieries, near Leeds, revived the idea of employing it in lieu of

horses to haul the coals along his tram-way. Mr. Blenkinsop, in the

patent which he took out for his proposed engine, followed in many

respects the design of Trevithick; but, with the help of Matthew

Murray, of Leeds, one of the most ingenious mechanics of his day, he

introduced several important and valuable modifications. Thus he

employed two cylinders of 8 in. diameter instead of one, as in

Trevithick's engine. These cylinders were placed vertically, and

immersed for more than half their length in the steam space of the

boiler. The eduction pipes met in a single tube at the top, and

threw the steam into the air. The boiler was cylindrical in form,

but of cast iron. It had one flue, the fire being at one end and the

chimney at the other. The engine was supported on a carriage without

springs, resting directly upon two pairs of wheels and axles

unconnected with the working parts, and which merely served to carry

the engine upon the rails. The motion was effected in this way: the

piston-rods, by means of cross-heads, worked the connecting-rods,

which came down to two cranks on each side below the boiler, placed

at right angles in order to pass their centres with certainty. These

cranks worked two shafts fixed across the engine, on which were

small-toothed wheels working into a larger one between them; and on

the axis of this large wheel, outside the framing, were the

driving-wheels, one of which was toothed, and worked into a rack on

one side of the railway.

It will be observed that the principal new features in this engine

were the two cylinders and the toothed-wheel working into a

rack-rail. Mr. Blenkinsop contrived the latter expedient in order to

insure sufficient adhesion between the wheel and the road, supposing

that smooth wheels and smooth rails would be insufficient for the

purpose. Clumsy and slow though the engine was compared with modem

locomotives, it was nevertheless a success. It was the first engine

that plied regularly upon any railway, doing useful work; and it

continued so employed for more than twenty years. What was more, it

was a commercial success, for its employment was found to be

economical compared with horse-power. In a letter to Sir John

Sinclair, Mr. Blenkinsop stated that his engine weighed five tons;

consumed two thirds of a hundred weight of coals and fifty gallons

of water per hour; drew twenty-seven wagons, weighing ninety-four

tons, on a dead level, at three and a half miles an hour, or fifteen

tons up an ascent of 2 in. in the yard; that when "lightly loaded"

it travelled at a speed of ten miles an hour; that it did the work

of sixteen horses in twelve hours; and that its cost was £400. Such

was Mr. Blenkinsop's own account of the performances of his engine,

which was for a long time regarded as one of the wonders of the

neighbourhood. [p.156]

The Messrs. Chapman, of Newcastle, in 1812 endeavoured to overcome

the same fictitious difficulty of the want of adhesion between the

wheel and the rail by patenting a locomotive to work along the road

by means of a chain stretched from one end of it to the other. This

chain was passed once round a grooved barrel-wheel under the centre

of the engine, so that when the wheel turned, the locomotive, as it

were, dragged itself along the railway. An engine constructed after

this plan was tried on the Heaton Railway, near Newcastle; but it

was so clumsy in action, there was so great a loss of power by

friction, and it was found to be so expensive and difficult to keep

in repair, that it was very soon abandoned. Another remarkable

expedient was adopted by Mr. Brunton, of the Butterley Works,

Derbyshire, who in 1813 patented his Mechanical Traveller, to go

upon legs working alternately like those of a horse. [p.157] But this engine never got beyond the experimental state, for, at its

very first trial, the driver, to make sure of a good start,

overloaded the safety-valve, when the boiler burst and killed a

number of the bystanders, wounding many more. These, and other

contrivances with the same object, projected about the same time,

show that invention was busily at work, and that many minds were

anxiously labouring to solve the problem of steam locomotion on

railways.

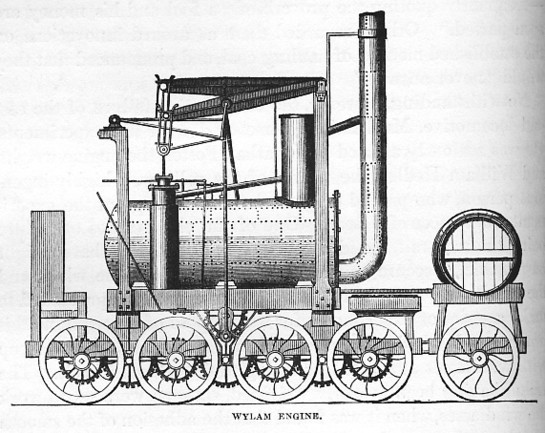

Mr. Blackett, of Wylam, was encouraged by the success of Mr.

Blenkinsop's experiment, and again he resolved to make a trial of

the locomotive upon his wagon-way. Accordingly, in 1812, he ordered

a second engine, which was so designed as to work with a toothed

driving-wheel upon a rack-rail as at Leeds. This locomotive was

constructed by Thomas Waters, of Gateshead, under the

superintendence of Jonathan Foster, Mr. Blackett's principal

engine-wright. It was a combination of Trevithick's and Blenkinsop's

engines; but it was of a more awkward construction than either. Like

Trevithick's, it had a single cylinder with a fly-wheel, which

Blenkinsop had discarded. The boiler was of cast iron. Jonathan

Foster described it to the author in 1854 as "a strange machine,

with lots of pumps, cog-wheels, and plugs, requiring constant

attention while at work." The weight of the whole was about six

tons.

When finished, it was conveyed to Wylam on a wagon, and there

mounted upon a wooden frame, supported by four pairs of wheels,

which had been constructed for its reception. A barrel of water,

placed on another frame upon wheels, was attached to it as a tender. After a great deal of labour, the cumbrous machine was got upon the

road. At first it would not move an inch. Its maker, Tommy Waters,

became impatient, and at length enraged, and, taking hold of the

lever of the safety-valve, declared in his desperation that "either

she or he should go." At length the machinery was set in motion, on

which, as Jonathan Foster described to the author, "she flew all to

pieces, and it was the biggest wonder i' the world that we were not

all blewn up.'' The incompetent and useless engine was declared to

be a failure; it was shortly after dismounted and sold; and Mr.

Blackett's praise-worthy efforts thus far proved in vain.

He was still, however, desirous of testing the practicability of

employing locomotive power in working the coal down to Lemington,

and he determined on making yet another trial. He accordingly

directed his engine-wright, Jonathan Foster, to proceed with the

building of a third engine in the Wylam workshops. This new

locomotive had a single 8-inch cylinder, was provided with a

fly-wheel like its predecessor, and the driving-wheel was cogged on

one side to enable it to travel in the rack-rail laid along the

road. The engine proved more successful than the former one, and it

was found capable of dragging eight or nine loaded wagons, though at

the rate of little more than a mile an hour, from the colliery to

the shipping-place. It sometimes took six hours to perform the

journey of five miles. Its weight was found too great for the road,

and the cast-iron plates were constantly breaking. It was also very

apt to get off the rack-rail, and then it stood still. The driver

was one day asked how he got on. "Get on?" said he, "we don't get

on; we only get off!" On such occasions, horses had to be sent out

to drag the wagons as before, and others to haul the engine back to

the workshops. It was constantly getting out of order; its plugs,

pumps, or cranks got wrong, and it was under repair as often as at

work. At length it became so cranky that the horses were usually

sent after it to drag it along when it gave up, and the workmen

generally declared it to be a "perfect plague." Mr. Blackett did not

obtain credit among his neighbours for these experiments. Many

laughed at his machines, regarding them only in the light of

crotchets—frequently quoting the proverb of "a fool and his money

are soon parted." Others regarded them as absurd innovations on the

established method of hauling coal, and pronounced that they would

"never answer."

Notwithstanding, however, the comparative failure of the second

locomotive, Mr. Blackett persevered with his experiments. He was

zealously assisted by Jonathan Foster, the engine-wright, and

William Hedley, the viewer of the colliery, a highly ingenious

person, who proved of great use in carrying out the experiments to a

successful issue. One of the chief causes of failure being the

rack-rail, the idea occurred to Mr. Hedley that it might be possible

to secure sufficient adhesion between the wheel and the rail by the

mere weight of the engine, and he proceeded to make a series of

experiments for the purpose of determining this problem. He had a

frame placed on four wheels, and fitted up with windlasses attached

by gearing to the several wheels. The frame having been properly

weighted, six men were set to work the windlasses, when it was found

that the adhesion of the smooth wheels on the smooth rails was quite

sufficient to enable them to propel the machine without slipping. Having then found the proportion which the power bore to the weight,

he demonstrated by successive experiments that the weight of the

engine would of itself produce sufficient adhesion to enable it to

draw upon a smooth railroad the requisite number of wagons in all

kinds of weather. And thus was the fallacy which had heretofore

prevailed on this subject completely exploded, and it was

satisfactorily proved that rack-rails, toothed wheels, endless

chains, and legs, were alike unnecessary for the efficient traction

of loaded wagons upon a moderately level road. [160-1]

From this time forward, considerably less difficulty was experienced

in working the coal-trains upon the Wylam tram-road. At length the

rack-rail was dispensed with. The road was laid with heavier rails;

the working of the old engine was improved; and a new engine was

shortly after built and placed upon the road, still on eight wheels,

driven by seven rack-wheels working inside them—with a wrought-iron

boiler through which the flue was returned so as largely to increase

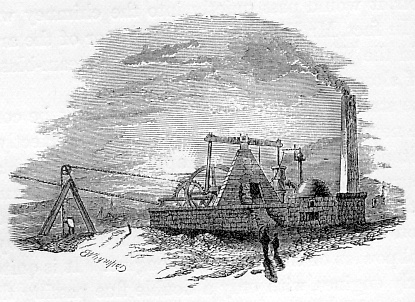

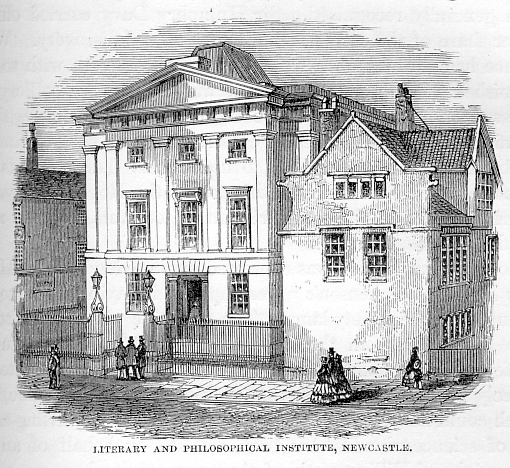

the heating surface, and thus give increased power to the engine. [p.160-2] Below is a representation of this improved Wylam engine.

As may readily be imagined, the jets of steam from the piston,

blowing off into the air at high pressure while the engine was in

motion, caused considerable annoyance to horses passing along the

Wylam road, at that time a public highway. The nuisance was felt to

be almost intolerable, and a neighbouring gentleman threatened to

have it put down. To diminish the noise as much as possible, Mr.

Blackett gave orders that so soon as any horse, or vehicle drawn by

horses, came in sight, the locomotive was to be stopped, and the

frightful blast of the engine thus suspended until the passing

animals had got out of sight. Much interruption was thus caused to

the working of the railway, and it excited considerable

dissatisfaction among the workmen. The following plan was adopted to

abate the nuisance: a reservoir was provided immediately behind the

chimney (as shown in the opposite cut) into which the waste steam

was thrown after it had performed its office in the cylinder, and

from this reservoir the steam gradually escaped into the atmosphere

without noise. This arrangement was devised with the express object

of preventing a blast in the chimney, the value of which, as we

shall subsequently find, was not detected until George Stephenson,

adopting it with a preconceived design and purpose, demonstrated its

importance and value—as being, in fact, the very life-breath of the

locomotive engine.

While Mr. Blackett was thus experimenting and building locomotives

at Wylam, George Stephenson was anxiously studying the same subject

at Killingworth. He was no sooner appointed engine-wright of the

collieries than his attention was directed to the means of more

economically hauling the coal from the pits to the river side. We

have seen that one of the first important improvements which he

made, after being placed in charge of the colliery machinery, was to

apply the surplus power of a pumping steam-engine fixed underground,

for the purpose of drawing the coals out of the deeper workings of

the Killingworth mines, by which he succeeded in effecting a large

reduction in the expenditure on manual and horse labour.

The coals, when brought above ground, had next to be laboriously

dragged by means of horses to the shipping staiths on the Tyne,

several miles distant. The adoption of a tram-road, it is true, had

tended to facilitate their transit; nevertheless, the haulage was

both tedious and expensive. With the view of economizing labour,

Stephenson laid down inclined planes where the nature of the ground

would admit of this expedient being adopted. Thus a train of full

wagons let down the incline by means of a rope running over wheels

laid along the tram-road, the other end of which was attached to a

train of empty wagons placed at the bottom of the parallel road on

the same incline, dragged them up by the simple power of gravity. But this applied only to a comparatively small part of the road. An

economical method of working the coal-trains, instead of by means of

horses—the keep of which was at that time very costly, in

consequence of the high price of corn—was still a great desideratum,

and the best practical minds in the collieries were actively engaged

in trying to solve the problem.

In the first place, Stephenson resolved to make himself thoroughly

acquainted with what had already been done. Mr. Blackett's engines

were working daily at Wylam, past the cottage where he had been

born, and thither he frequently went to inspect the improvements

made by Mr. Blackett from time to time both in the locomotive and in

the plate-way along which it worked. [p.162] Jonathan Foster informed us that, after one of these visits,

Stephenson declared to him his conviction that a much more effective

engine might be made, that should work more steadily and draw the

load more effectively.

He had also the advantage, about the same time, of seeing one of

Blenkinsop's Leeds engines, which was placed on the tram-way leading

from the collieries of Kenton and Coxlodge, on the 2d September,

1813. This locomotive drew sixteen chaldron wagons, containing an

aggregate weight of seventy tons, at the rate of about three miles

an hour. George Stephenson and several of the Killingworth men were

among the crowd of spectators that day; and after examining the

engine and observing its performances, he remarked to his companions

that "he thought he could make a better engine than that, to go upon

legs." Probably he had heard of the invention of Brunton, whose

patent had by this time been published, and proved the subject of

much curious speculation in the colliery districts. Certain it is

that, shortly after the inspection of the Coxlodge engine, he

contemplated the construction of a new locomotive, which was to

surpass all that had preceded it. He observed that those engines

which had been constructed up to this time, however ingenious in

their arrangements, were in a great measure practical failures. Mr.

Blackett's was as yet both clumsy and expensive. Chapman's had been

removed from the Heaton tram-way in 1812, and was regarded as a

total failure. And the Blenkinsop engine at Coxlodge was found very

unsteady and costly in its working; besides, it pulled the rails to

pieces, the entire strain being upon the rack-rail on one side of

the road. The boiler, however, having shortly blown up, there was an

end of that engine, and the colliery owners did not feel encouraged

to try any farther experiment.

An efficient and economical working locomotive engine, therefore,

still remained to be invented, and to accomplish this object

Stephenson now applied himself. Profiting by what his predecessors

had done, warned by their failures and encouraged by their partial

successes, he commenced his labours. There was still wanting the man

who should accomplish for the locomotive what James Watt had done

for the steam-engine, and combine in a complete form the best points

in the separate plans of others, embodying with them such original

inventions and adaptations of his own as to entitle him to the merit

of inventing the working locomotive, as James Watt is to be regarded

as the inventor of the working condensing engine. This was the great

work upon which George Stephenson now entered, though probably

without any adequate idea of the ultimate importance of his labours

to society and civilization.

He proceeded to bring the subject of constructing a "Travelling

Engine," as he then denominated the locomotive, under the notice of

the lessees of the Killingworth Colliery, in the year 1813. Lord

Ravensworth, the principal partner, had already formed a very

favourable opinion of the new colliery engine-wright from the

improvements which he had effected in the colliery engines, both

above and below ground; and, after considering the matter, and

hearing Stephenson's explanations, he authorized him to proceed with

the construction of a locomotive, though his lordship was by some

called a fool for advancing money for such a purpose. "The first

locomotive that I made," said Stephenson, many years after, when

speaking of his early career at a public meeting in Newcastle, "was

at Killingworth Colliery, and with Lord Ravensworth's money. [p.164] Yes, Lord Ravensworth and partners were the first to intrust me,

thirty-two years since, with money to make a locomotive engine. I

said to my friends, there was no limit to the speed of such an

engine, if the works could be made to stand."

Our engine-wright had, however, many obstacles to encounter before

he could get fairly to work with the erection of his locomotive. His

chief difficulty was in finding workmen sufficiently skilled in

mechanics and in the

use of tools to follow his instructions and embody his designs in a

practical shape. The tools then in use about the collieries were

rude and clumsy, and there were no such facilities as now exist for

turning out machinery of an entirely new character. Stephenson was

under the necessity of working with such men and tools as were at

his command, and he had in a great measure to train and instruct the

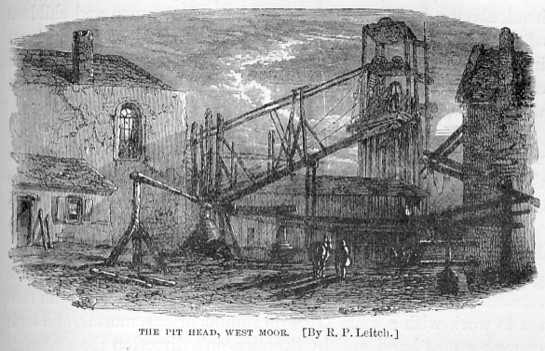

workmen himself. The engine was built in the workshops at the West

Moor, the leading mechanic being John Thirlwall, the colliery

blacksmith, an excellent mechanic in his way, though quite new to

the work now intrusted to him.

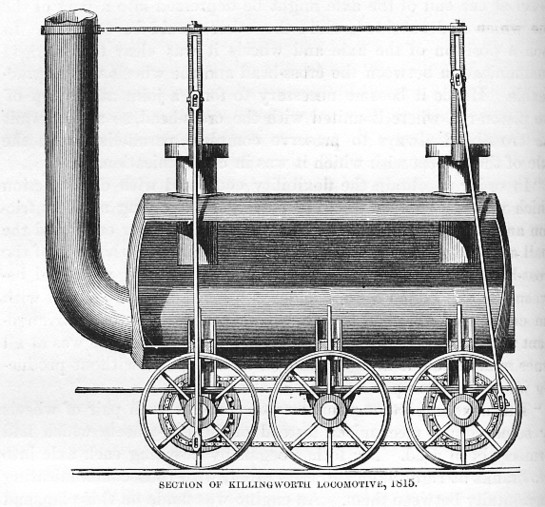

In this first locomotive constructed at Killingworth, Stephenson to

some extent followed the plan of Blenkinsop's engine. The

wrought-iron boiler was cylindrical, eight feet in length and

thirty-four inches in diameter, with an internal flue-tube twenty

inches wide passing through it. The engine had two vertical

cylinders of eight inches diameter and two feet stroke let into the

boiler, which worked the propelling gear with cross-heads and

connecting-rods. The power of the two cylinders was combined by

means of spur-wheels, which communicated the motive power to the

wheels supporting the engine on the rail, instead of, as in

Blenkinsop's engine, to cog-wheels which acted on the cogged rail

independent of the four supporting wheels. The engine thus worked

upon what is termed the second motion. The chimney was of wrought

iron, round which was a chamber extending back to the feed-pumps,

for the purpose of heating the water previous to its injection into

the boiler. The engine had no springs, and was mounted on a wooden

frame supported on four wheels. In order to neutralize as much as

possible the jolts and shocks which such an engine would necessarily

encounter from the obstacles and inequalities of the then very

imperfect plateway, the water-barrel which served for a tender was

fixed to the end of a lever and weighted, the other end of the lever

being connected with the frame of the locomotive carriage. By this

means the weight of the two was more equally distributed, though the

contrivance did not by any means compensate for the total absence of

springs.

The wheels of the locomotive were all smooth, Stephenson having

satisfied himself by experiment that the adhesion between the wheels

of a loaded engine and the rail would be sufficient for the purpose

of traction. Robert Stephenson informed us that his father caused a

number of workmen to mount upon the wheels of a wagon moderately

loaded, and throw their entire weight upon the spokes on one side,

when he found that the wagon could thus be easily propelled forward

without the wheels slipping. This, together with other experiments,

satisfied him, as it had already satisfied Mr. Hedley, of the

expediency of adopting smooth wheels on his engine, and it was so

made accordingly.

The engine was, after much labour and anxiety, and frequent

alterations of parts, at length brought to completion, having been

about ten months in hand. It was placed upon the Killingworth

Railway on the 25th of July, 1814, and its powers were tried on the

same day. On an ascending gradient of 1 in 450, the engine succeeded

in drawing after it eight loaded carriages of thirty tons' weight at

about four miles an hour; and for some time after it continued

regularly at work.

Although a considerable advance upon previous locomotives, "Blucher"

(as the engine was popularly called) was nevertheless a somewhat

cumbrous and clumsy machine. The parts were huddled together. The

boiler constituted the principal feature; and, being the foundation

of the other parts, it was made to do duty not only as a generator

of steam, but also as a basis for the fixings of the machinery and

for the bearings of the wheels and axles. The want of springs was

seriously felt; and the progress of the engine was a succession of

jolts, causing considerable derangement to the machinery. The mode

of communicating the motive power to the wheels by means of the

spur-gear also caused frequent jerks, each cylinder alternately

propelling or becoming propelled by the other, as the pressure of

the one upon the wheels became greater or less than the pressure of

the other; and, when the teeth of the cog-wheels became at all worn,

a rattling noise was produced during the travelling of the engine.

As the principal test of the success of the locomotive was its

economy as compared with horse-power, careful calculations were made

with the view of ascertaining this important point. The result was,

that it was found the working of the engine was at first barely

economical; and at the end of the year the steam-power and the

horse-power were ascertained to be as nearly as possible upon a par

in dint of cost.

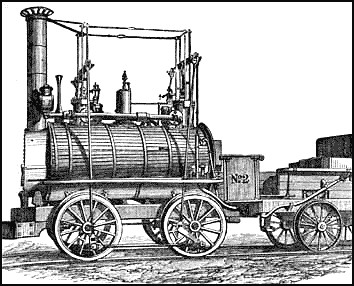

We give the remainder of the history of George Stephenson's efforts

to produce an economical working locomotive in the words of his son

Robert, as communicated to the author in 1856, for the purposes of

his father's "life."

"A few months of experience and careful observation upon the

operation of this (his first) engine convinced my father that the

complication arising out of the action of the two cylinders being

combined by spur-wheels would prevent their coming into practical

application. He then directed his attention to an entire change in

the construction and mechanical arrangements, and in the following

year took out a patent, dated February 28th, 1816, for an engine

which combined in a remarkable degree the essential requisites of an

economical locomotive—that is to say, few parts, simplicity in their

action, and great simplicity in the mode by which power was

communicated to the wheels supporting the engine.

"This second engine consisted as before of two vertical cylinders,

which communicated directly with each pair of the four wheels that

supported the engine by a cross-head and a pair of connecting-rods;

but, in attempting to establish a direct communication between the

cylinders and the wheels that rolled upon the rails, considerable

difficulties presented themselves. The ordinary joints could not be

employed to unite the engine, which was a rigid mass, with the

wheels rolling upon the irregular surface of the rails; for it was

evident that the two rails of the line of railway could not always

be maintained at the same level with respect to each other—that one

wheel at the end of the axle might be depressed into a part of the

line which had subsided, while the other would be elevated. In such

a position of the axle and wheels it was clear that a rigid

communication between the cross-head and the wheels was

impracticable. Hence it became necessary to form a joint at the top

of the piston-rod where it united with the cross-head, so as to

permit the cross-head always to preserve complete parallelism with

the axle of the wheels with which it was in communication.

"In order to obtain the flexibility combined with direct action

which was essential for insuring power and avoiding needless

friction and jars from irregularities in the rail, my father

employed the 'ball and socket' joint for effecting a union between

the ends of the cross-heads where they united with the

connecting-rods, and between the end of the connecting-rods where

they were united with the crank-pins attached to each driving-wheel.

By this arrangement the parallelism between the cross-head and the

axle was at all times maintained, it being permitted to take place

without producing jar or friction upon any part of the machine.

"The next important point was to combine each pair of wheels by some

simple mechanism, instead of the cog-wheels which had formerly been

used. My father began by inserting each axle into two cranks at

right angles to each other, with rods communicating horizontally

between them. An engine was made on this plan, and answered

extremely well. But at that period (1815) the mechanical skill of

the country was not equal to the task of forging cranked axles of

the soundness and strength necessary to stand the jars incident to

locomotive work; so my father was compelled to fall back upon a

substitute which, though less simple and less efficient, was within

the mechanical capabilities of the workmen of that day, either for

construction or repair. He adopted a chain which rolled over

indented wheels placed on the centre of each axle, and so arranged

that the two pairs of wheels were effectually coupled and made to

keep pace with each other. But these chains after a few years' use

became stretched, and then the engines were liable to irregularity

in their working, especially in changing from working back to

forward again. Nevertheless, these engines continued in profitable

use upon the Killingworth Colliery Railway for some years.

Eventually the chain was laid aside, and the front and hind wheels

were united by rods on the outside, instead of by rods and

crank-axles inside, as specified in the original patent; and this

expedient completely answered the purpose required, without

involving any expensive or difficult workmanship.

"Another important improvement was introduced in this engine. The

eduction steam had hitherto been allowed to escape direct into the

open atmosphere; but my father, having observed the great velocity

with which the waste-steam escaped, compared with the velocity with

which the smoke issued from the chimney of the same engine, thought

that by conveying the eduction steam into the chimney, and there

allowing it to escape in a vertical direction, its velocity would be

imparted to the smoke from the engine, or to the ascending current

of air in the chimney. The experiment was no sooner made than the

power of the engine became more than doubled; combustion was

stimulated, as it were, by a blast; consequently, the power of the

boiler for generating steam was increased, and, in the same

proportion, the useful duty of the engine was augmented.

"Thus, in 1815, my father had succeeded in manufacturing an engine

which included the following important improvements on all previous

attempts in the same direction: simple and direct communication

between the cylinder and the wheels rolling upon the rails; joint

adhesion of all the wheels, attained by the use of horizontal

connecting-rods; and, finally, a beautiful method of exciting the

combustion of fuel by employing the waste steam which had formerly

been allowed uselessly to escape. It is, perhaps, not too much to

say that this engine, as a mechanical contrivance, contained the

germ of all that has since been effected. It may be regarded, in

fact, as a type of the present locomotive engine.

Stephenson's locomotive for Killingworth Colliery.

"In describing my father's application of the waste steam for the

purpose of increasing the intensity of combustion in the boiler, and

thus increasing the power of the engine without adding to its

weight, and while claiming for this engine the merit of being a type

of all those which have been successfully devised since the

commencement of the Liverpool and Manchester Railway, it is

necessary to observe that the next great improvement in the same

direction, the 'multitubular boiler,' which took place some years

later, could never have been used without the help of that simple

expedient, the steamblast, by which power only the burning of

coke was rendered possible.

"I can not pass over this last-named invention of my father's

without remarking how slightly, as an original idea, it has been

appreciated; and yet how small would be the comparative value of the

locomotive engine of the present day without the application of that

important invention!

"Engines constructed by my father in the year 1818 upon the

principles just described are in use on the Killingworth Colliery

Railway to this very day (1866), conveying, at the speed of perhaps

five or six miles an hour, heavy coal-trains, probably as

economically as any of the more perfect engines now in use.

"There was another remarkable piece of ingenuity in this machine,

which was completed so many years before the possibility of

steam-locomotion became an object of general commercial interest and

Parliamentary inquiry. I have before observed that up to and after

the year 1818 there was no such class of skilled mechanics, nor were

there such machinery and tools for working in metals, as are now at

the disposal of inventors and manufacturers. Among other

difficulties of a similar character, it was not possible at that

time to construct springs of sufficient strength to support the

improved engines. The rails then used being extremely light, the

roads became worn down by the traffic, and occasionally the whole

weight of the engine, instead of being uniformly distributed over

four wheels, was thrown almost diagonally upon two. In order to

avoid the danger arising from such irregularities in the road, my

father arranged the boiler so that it was supported upon the frame

of the engine by four cylinders which opened into the interior of

the boiler. These cylinders were occupied by pistons with rods,

which passed downward and pressed upon the upper side of the axles. The cylinders, opening into the interior of the boiler, allowed the

pressure of steam to be applied to the upper side of the piston, and

that pressure being nearly equal to the support of one fourth of the

weight of the engine, each axle, whatever might be its position, had

the same amount of weight to bear, and consequently the entire

weight was at all times nearly equally distributed among the wheels. This expedient was more necessary in this case, as the weight of the

new locomotive engines far exceeded that of the carriages which had

hitherto been used upon colliery railways, and therefore subjected

the rails to much greater risk from breakage. And this mode of

supporting the engine remained in use until the progress of

spring-making had considerably advanced, when steel springs of

sufficient strength superseded this highly ingenious mode of

distributing the weight of the engine uniformly among the wheels."

The invention of the Steam-blast by George Stephenson in 1815 was

fraught with the most important consequences to railway locomotion,

and it is not saying too much to aver that the success of the

locomotive has been in a great measure the result of its adoption. Without the steam-blast, by means of which the intensity of

combustion is maintained at its highest point, producing a

correspondingly rapid evolution of steam, high rates of speed could

not have been kept up; the advantages of the multitubular boiler

(afterward invented) could never have been fully tested; and

locomotives might still have been dragging themselves unwieldily

along at little more than five or six miles an hour.

As this invention has been the subject of considerable controversy,

it becomes necessary to add a few words respecting it in this place.

It has been claimed as the invention of Trevithick in 1804, of

Hedley in 1814, of Goldsworthy Gurney in 1820, and of Timothy

Hackworth in 1829. With respect to Trevithick, it appears that he

discharged the waste steam into the chimney of his engine, but

without any intention of thereby producing a blast; [p.171] and that

he attached no value to the expedient is sufficiently obvious from

the fact that in 1815 he took out a patent for urging the fire by

means of fanners, similar to a winnowing machine. The claim put

forward on behalf of William Hedley, that he invented the blast-pipe

for the Wylam engine, is sufficiently contradicted by the fact that

the Wylam engine had no blast-pipe. "I remember the Wylam engine,"

Robert Stephenson wrote to the author in 1857, "and I am positive

there was no blast-pipe." On the contrary, the Wylam engine embodied

a contrivance for the express purpose of preventing a blast. This is

clearly shown by the drawing and description of it contained in the

first edition of Nicholas Wood's "Practical Treatise on Railroads,"

published in 1825. This evidence is all the more valuable for our

purpose as it was published long before any controversy had arisen

as to the authorship of the invention, and, indeed, before it was

believed that any merit whatever belonged to it. And it is the more

remarkable, as Nicholas Wood himself, who published the first

practical work on railways, did not at that time approve of the

steam-blast, and referred to the Wylam engine in illustration of how

it might be prevented.

The following passage from Mr. Wood's book clearly describes the

express object and purpose for which George Stephenson invented and

applied the steam-blast in the Killingworth engines. Describing

their action, Mr. Wood says:

"The steam is admitted to the top and bottom of the

piston by means of a sliding valve, which, being moved up and down

alternately, opens a communication between the top and bottom of the

cylinder and the pipe that is open into the chimney and turns up

within it. The steam, after performing its office within the

cylinder, is thus thrown into the chimney, and the power with which

it issues will be proportionate to the degree of elasticity; and

the exit being directed upwards accelerates the velocity of the

current of heated air accordingly." [p.172-1]

And again, at another part of the book, he says:

"There is another great objection urged against

locomotives, which is, the noise that the steam makes in escaping

into the chimney; this objection is very singular, as it is not the

result of any inherent form in the organization of such engines, but

an accidental circumstance. When the engines were first made,

the steam escaped into the atmosphere, and made comparatively little

noise; it was found difficult then to produce steam in sufficient

quantity to keep the engine constantly working, or rather to obtain

an adequate rapidity of current in the chimney to give sufficient

intensity to the fire. To effect a greater rapidity or to increase

the draught of the chimney. Mr. Stephenson thought that by causing

the steam, to escape into the chimney through a pipe with its end

turned upward, the velocity of the current would be accelerated, and

such was the effect; but, in remedying one evil, another has

been produced, which, though objectionable in some places, was not

considered as objectionable on a private railroad. The tube through

the boiler having been increased, there is now no longer any

occasion for the action of the steam to assist the motion of the

heated air in the chimney. The steam thrown in this manner into the

chimney acts as a trumpet, and certainly makes a very disagreeable

noise. Nothing, however, is more easy to remedy, and the very act of

remedying this defect will also be the means of economizing the

fuel." [p.172-2]

Mr. Wood then proceeds to show how the noise caused by the

blast—how, in fact, the blast itself, might be effectually prevented

by adopting the expedient employed in the Wylam engine; which was,

to send the exhaust steam, not into the chimney (where alone the

blast could act with effect by stimulating the draught), but into a

steam-reservoir provided for the purpose. His words are these:

"Nothing more is wanted to destroy the noise than

to cause the steam to expand itself into a reservoir, and then allow

it to escape gradually to the atmosphere through the chimney. Upon the Wylam railroad the noise was made the subject of complaint

by a neighbouring gentleman, and they adopted this mode, which had

the effect above mentioned." [p.173]

It is curious to find that Mr. Nicholas Wood continued to object to

the use of the steam-blast down even to the time when the Liverpool

and Manchester Railway Bill was before Parliament. In his evidence

before the Committee on that Bill in 1825, he said: "Those engines

[at Killingworth] puff very much and the object is to get

an increased draught in the chimney. Now (by enlarging the

flue-tube and giving it a double turn through the boiler) we have

got a sufficiency of steam without it, and I have no doubt, by

allowing the steam to exhaust itself in a reservoir, it would pass

quietly into the chimney without that noise." In fact, Mr. Wood was

still in favour of the arrangement adopted in the Wylam engine, by

which the steam-blast had been got rid of altogether.

If these statements, made in Mr. Wood's book, be correct—and they

have never been disputed—they render it perfectly clear that George

Stephenson invented and applied the steam-blast for the express

purpose of quickening combustion in the furnace by increasing the

draught in the chimney. Although urged by Wood to abandon the blast,

Stephenson continued to hold by it as one of the vital powers of the

locomotive engine. It is quite true that in the early engines, with

only a double flue passing through the boiler, run as they were at

low speeds, the blast was of comparatively less importance. It was

only when the improved passenger engine, fitted with the

multitubular boiler, was required to be run at high speeds that the

full merits of the blast were brought out; and in detecting its

essential uses in this respect, and sharpening it for the purpose of

increasing its action, the sagacity of Timothy Hackworth, of

Darlington, is entitled to due recognition.

――――♦――――

CHAPTER VI.

INVENTION OF THE "GEORDY" SAFETY-LAMP.

EXPLOSIONS of

fire-damp were unusually frequent in the coal-mines of

Northumberland and Durham about the time when George Stephenson was

engaged in the construction of his first locomotives. These

explosions were often attended with fearful loss of life and

dreadful suffering to the work-people. Killingworth Colliery was not

free from such deplorable calamities; and during the time that

Stephenson was employed as brakesman at the West Moor, several

"blasts" took place in the pit, by which many workmen were scorched

and killed, and the owners of the colliery sustained heavy losses.

One of the most serious of these accidents occurred in 1806, not

long after he had been appointed brakesman, by which ten persons

were killed. Stephenson was near the pit mouth at the time, and the

circumstances connected with the explosion made a deep impression on

his mind, as appears from the graphic account which he gave of it to

the Committee of the House of Commons on accidents in mines, some

thirty years after the event.

"The pit," said he,

"had just ceased drawing coals, and nearly all

the men had got out. It was some time in the afternoon, a little

after midday. There were five men that went down the pit; four of

them for the purpose of preparing a place for the furnace. The fifth

was a person who went down to set them to work. I sent this man down

myself, and he had just got to the bottom of the shaft about two or

three minutes when the explosion took place. I had left the mouth of

the pit, and had gone about fifty or sixty yards away, when I heard

a tremendous noise, looked round, and saw the discharge come out of

the pit like the discharge of a cannon. It continued to blow, I

think, for a quarter of an hour, discharging every thing that had

come into the current. Wood came up, stones came up, and trusses of

hay that went up into the air like balloons. Those trusses had been

sent down during the day, and I think they had in some measure

injured the ventilation of the mine. The ground all round the top of

the pit was in a trembling state. I went as near as I durst go;

every thing appeared cracking and rending about me. Part of the

brattice, which was very strong, was blown away at the bottom of the

pits. Very large pumps were lifted from their places, so that the

engine could not work. The pit was divided into four by partitions;

it was a large pit, fourteen feet in diameter, and partitions were

put down at right angles, which made four compartments. The

explosion took place in one of those four quarters, but it broke

through into all the others at the bottom, and the brattice or

partitions were set on fire at the first explosion.

"Nobody durst go near the shafts for some time, for fear of another

explosion taking place. At last we considered it necessary to run

the rope backward and forward, and give the miners, if there were

any at the bottom of the shaft, an opportunity of catching the rope

as it came to the bottom. Several men were safely got up in this

way; one man, who had got hold of the rope, was being drawn up, when

a farther explosion took place while he was still in the shaft, and

the increased current which came about him projected him as it were

up the shaft; yet he was landed without injury: it was a singular

case. . . . The pit continued to blast every two or three hours for

about two days. It appears that the coal had taken fire, and as soon

as the carburetted hydrogen gas, collected in sufficient quantity to

reach the part where it was burning, it ignited again; but none of

the explosions were equal to the first, on account of many parts of

the mine having become filled with azotic gas, or the after-damp

of the mine. All the ditches in the country-side were stopped to get

water to pour into the pit. We had fire-engines brought from

Newcastle, and the water was poured in till it came above the fire,

and then it was extinguished. The loss to the owners of the colliery

by this accident must have been about £20,000." [p.176]

Another explosion took place in the same pit in 1809, by which

twelve persons lost their lives. The blast did not reach the shaft

as in the former case, the unfortunate persons in the pit having

been suffocated by the after-damp. More calamitous still were the

explosions which took place in the neighbouring collieries, one the

of the worst being that of 1812, in the Felling Pit near Gateshead,

a mine belonging to Mr. Brandling, by which no fewer than ninety men

and boys were suffocated or burnt to death; and a similar accident

occurred in the same pit in the year following, by which twenty-two

men and boys perished.

It was natural that Stephenson should devote his attention to the

causes of these deplorable accidents, and to the means by which they

might, if possible, be prevented. His daily occupation led him to

think much and deeply on the subject. As engine-wright of a colliery

so extensive as that of Killingworth, where there were nearly 160

miles of gallery excavation, in which he personally superintended

the working of inclined planes, along which the coals were sent to

the pit entrance, he was necessarily very often under ground, and

brought face to face with the dangers of fire-damp. From fissures in

the roofs of the galleries carburetted hydrogen gas was constantly

flowing; and in some of the more dangerous places it might be heard

escaping from the crevices of the coal with a hissing noise.

Ventilation, firing, and all conceivable modes of drawing out the

foul air had been tried, while the more dangerous parts of the

galleries were built up. Still the danger could not be wholly

prevented. The miners must necessarily guide their steps through the

extensive underground ways with lighted lamps or candles, the naked

flame of which, coming in contact with the inflammable air, daily

exposed them and their fellow-workers in the pit to the risk of

death in one of its most dreadful forms.

One day in the year 1814, a workman hurried into Stephenson's

cottage with the startling information that the deepest main of the

colliery was on fire! He immediately hastened to the pit-head, about

a hundred yards off, whither the women and children of the colliery

were running, with wildness and terror depicted in every face. In a

commanding voice, Stephenson ordered the engine-man to lower him

down the shaft in the corve. There was danger, it might be death,

before him, but he must go.

He was soon at the bottom, and in the midst of the men, who were

paralyzed at the danger which threatened the lives of all in the

pit. Leaping from the corve on its touching the ground, he called

out, "Are there six men among you who have the courage to follow me? If so, come, and we will put the fire out." The Killingworth pitmen

had the most perfect confidence in their engine-wright, and they

readily volunteered to follow him. Silence succeeded the frantic

tumult of the previous minute, and the men set to work with a will.

In every mine, bricks, mortar, and tools enough are at hand, and by

Stephenson's direction the materials were forthwith carried to the

required spot, where, in a very short time, a wall was raised at the

entrance to the main, he himself taking the most active part in the

work. The atmospheric air was by this means excluded, the fire was

extinguished, most of the people in the pit were saved from death,

and the mine was preserved.

This anecdote of George Stephenson was related to the writer, near

the pit-mouth, by one of the men. Kit Heppel, who had been present,

and helped to build up the brick wall by which the fire was stayed,

though several of the workmen were suffocated. Heppel relates that,

when down the pit some days after, seeking out the dead bodies, the

cause of the accident was the subject of some conversation between

himself and Stephenson, and Heppel then asked him, "Can nothing be

done to prevent such awful occurrences?" Stephenson replied that he

thought something might be done. "Then," said Heppel, "the sooner

you begin the better, for the price of coal-mining now is

pitmen's lives."

Fifty years since, many of the best pits were so full of the

inflammable gas given forth by the coal that they could not be

worked without the greatest danger, and for this reason some were

altogether abandoned. The rudest possible means were adopted of

producing light sufficient to enable the pitmen to work by. The

phosphorescence of decayed fish-skins was tried; but this, though

safe, was very inefficient. The most common method employed was what

was called a steel mill, the notched wheel of which, being made to

revolve against a flint, struck a succession of sparks, which

scarcely served to do more than make the darkness visible. A boy

carried the apparatus, working the wheel; and by the imperfect light

thus given forth the miner plied his dangerous trade. Candles were

only used in those parts of the pit where gas was not abundant. Under this rude system not more than one third of the coal could be

worked, while two thirds were left.

What the workmen, not less than the coal-owners, eagerly desired was

a lamp that should give forth sufficient light, without

communicating flame to the inflammable gas which accumulated in

certain parts of the pit. Something had already been done toward the

invention of such a lamp by Dr. Clanny, of Sunderland, who, in 1818,

contrived an apparatus to which he gave air from the mine through

water, by means of bellows. This lamp went out of itself in

inflammable gas. It was found, however, too unwieldy to be used by

the miners for the purposes of their work, and did not come into

general use. A committee of gentlemen interested in coal-mining was

formed to investigate the causes of the explosions, and to devise,

if possible, some means of preventing them. At the invitation of

that committee, Sir Humphry Davy, then in the full zenith of his

reputation, was requested to turn his attention to the subject. He

accordingly visited the collieries near Newcastle on the 24th of

August, 1815, and at the close of that year, on the 9th of November,

1815, he read before the Royal Society of London his celebrated

paper "On the Fire-damp of Coal Mines, and on Methods of Lighting

the Mine so as to prevent its Explosion."

But a humbler though not less diligent and original thinker had been

at work before him, and had already practically solved the problem

of the Safety-lamp. Stephenson was, of course, well aware of the

desire which prevailed in the colliery districts for the invention

of a lamp which should give light enough for the miners to work by

without exploding the fire-damp, and the painful incidents above

described only served to quicken his eagerness to master the

difficulty.

For several years he had been engaged, in his own rude way, in

making experiments with the fire-damp in the Killingworth mine. The

pitmen used to expostulate with him on these occasions, believing

the experiments to be fraught with danger. One of the sinkers,

called M'Crie, observing him holding up lighted candles to the

windward of the "blower" or fissure from which the inflammable gas

escaped, entreated him to desist; but Stephenson's answer was, that

"he was busy with a plan by which he hoped to make his experiments

useful for preserving men's lives." On these occasions the miners

usually got out of the way before he lit the gas.

In 1815, although he was very much occupied with the business of the

collieries and the improvement of his locomotive engine, he was also

busily engaged in making experiments upon the inflammable gas in the

Killingworth Pit. As he himself afterward related to the Committee

of the House of Commons which sat on the subject of Accidents in

Mines in 1835, he imagined that if he could construct a lamp with a

chimney so arranged as to cause a strong current, it would not fire

at the top of the chimney, as the burnt air would ascend with such a

velocity as to prevent the inflammable air of the pit from

descending toward the flame; and such a lamp, he thought, might be

taken into a dangerous atmosphere without risk of exploding.

Such was Stephenson's theory, when he proceeded to embody his idea

of a miner's safety-lamp in a practical form. In the month of

August, 1815, he requested his friend Nicholas Wood, the head

viewer, to prepare a drawing of a lamp according to the description

which he gave him. After several evenings' careful deliberations,

the drawing was prepared, and it was shown to several of the head

men about the works. "My first lamp," said Stephenson, describing it

to the committee above referred to, "had a chimney at the top of the

lamp, and a tube at the bottom to admit the atmospheric air, or

fire-damp and air, to feed the burner or combustion of the lamp. I

was not aware of the precise quantity required to feed the

combustion; but to know what quantity was necessary, I had a slide

at the bottom of the tube in my first lamp, to admit such a quantity

of air as might eventually be found necessary to keep up the

combustion."

Accompanied by his friend Wood, Stephenson went into Newcastle, and

ordered a lamp to be made according to his plan by the Messrs. Hogg,

tinmen, at the head of the Side—a well-known street in Newcastle. At

the same time, he ordered a glass to be made for the lamp at the

Northumberland Glass-house in the same town. This lamp was received

from the makers on the 21st of October, and was taken to

Killingworth for the purpose of immediate experiment.

"I remember that evening as distinctly as if it had been but

yesterday," said Robert Stephenson, describing the circumstances to

the author in 1857. "Moodie came to our cottage about dusk, and

asked 'if father had got back with the lamp.' 'No.' 'Then I'll wait

till he comes,' said Moodie; 'he can't be long now.' In about half

an hour, in came my father, his face all radiant. He had the lamp

with him! It was at once uncovered and shown to Moodie. Then it was

filled with oil, trimmed, and lighted. All was ready, only the head

viewer hadn't arrived. 'Run over to Benton for Nichol, Robert,' said

my father to me, 'and ask him to come directly; say we're going down

the pit to try the lamp.' By this time it was quite dark, and off I

ran to bring Nicholas Wood. His house was at Benton, about a mile

off. There was a short cut through Benton Church-yard, but just as I

was about to pass the wicket I saw what I thought was a white figure

moving about among the grave-stones. I took it for a ghost! My heart

fluttered, and I was in a great fright, but to Nichol's house I must

get, so I made the circuit of the churchyard; and when I got round

to the other side I looked, and, lo! the figure was still there. But

what do you think it was? Only the grave-digger, plying his work at

that late hour by the light of his lantern set upon one of the

grave-stones! I found Wood at home, and in a few minutes he was

mounted and off to my father's. When I got home I was told they had

just left—it was then about eleven—and gone down the shaft to try

the lamp in one of the most dangerous parts of the mine."

Arrived at the bottom of the shaft with the lamp, the party directed

their steps toward one of the foulest galleries in the pit, where

the explosive gas was issuing through a blower in the roof of the

mine with a loud hissing noise. By erecting some deal boarding round

that part of the gallery into which the gas was escaping, the air

was thus made more foul for the purpose of the experiment. After

waiting about an hour, Moodie, whose practical experience of

fire-damp in pits was greatest than that of either Stephenson or

Wood, was requested to go into the place which had thus been made

foul; and, having done so, he returned, and told them that the smell

of the air was such that if a lighted candle were now introduced an

explosion must inevitably take place. He cautioned Stephenson as to

the danger both to themselves and to the pit if the gas took fire;

but Stephenson declared his confidence in the safety of his lamp,

and, having lit the wick, he boldly proceeded with it toward the

explosive air. The others, more timid and doubtful, hung back when

they came within hearing of the blower; and, apprehensive of the

danger, they retired into a safe place, out of sight of the lamp,

which gradually disappeared with its bearer in the recesses of the

mine. It was a critical moment, and the danger was such as would

have tried the stoutest heart. Stephenson, advancing alone, with his

yet untried lamp, in the depths of those underground workings,

calmly venturing his life in the determination to discover a mode by

which the lives of many might be saved, and death disarmed in these

fatal caverns, presented an example of intrepid nerve and manly

courage more noble even than that which, in the excitement of battle

and the collective impetuosity of a charge, carries a man up to the

cannon's mouth.

Advancing to the place of danger, and entering within the fouled

air, his lighted lamp in hand, Stephenson held it firmly out, in the

full current of the blower, and within a few inches of its mouth. Thus exposed, the flame of the lamp at first increased, then

flickered, and then went out; but there was no explosion of the gas. Returning to his companions, who were still at a distance, he told

them what had occurred. Having now acquired somewhat more

confidence, they advanced with him to a point from which they could

observe the experiment repeated, but still at a safe distance. They

saw that when the lighted lamp was held within the explosive

mixture, there was a great flame; the lamp was almost full of fire;

and then it seemed to be smothered out. Again returning to his

companions, he re-lighted the lamp, and repeated the experiment. This was done several times, with the same result. At length Wood

and Moodie ventured to advance close to the fouled part of the pit;

and, in making some of the later trials, Mr. Wood himself held up

the lighted lamp to the blower. [p.183]

Such was the result of the first experiments with the first

practical Miner's Safety-lamp, and such was the daring

resolution of its inventor in testing its qualities.

Before leaving the pit, Stephenson expressed his opinion that, by an

alteration of the lamp which he contemplated, he could make it burn

better. This was by a change in the slide through which the air was

admitted into the lower part of the lamp, under the flame. After

making some experiments on the air collected at the blower, by means

of bladders which were mounted with tubes of various diameters, he

satisfied himself that, when the tube was reduced to a certain

diameter, the explosion would not pass through; and he fashioned his

slide accordingly, reducing the diameter of the tube until he

conceived it was quite safe. In about a fortnight the experiments

were repeated in the pit, in a place purposely made foul as before. On this occasion a larger number of persons ventured to witness the

experiments, which again proved successful. The lamp was not yet,

however, so efficient as the inventor desired. It required, he

observed, to be kept very steady when burning in the inflammable

gas, otherwise it was liable to go out, in consequence, as he

imagined, of the contact of the burnt air (as he then called it), or

azotic gas, which lodged round the exterior of the flame. If the

lamp was moved backward and forward, the azote came in contact with

the flame and extinguished it. "It struck me," said he, "that if I

put more tubes in, I should discharge the poisonous matter that hung

round the flame by admitting the air to its exterior part."

Although he had then no access to scientific works, nor intercourse

with scientific men, nor any thing that could assist him in his

inquiries on the subject besides his own indefatigable spirit of

inquiry, Stephenson contrived a rude apparatus, by means of which he

proceeded to test the explosive properties of the gas and the

velocity of current (for this was the direction of his inquiries)

required to permit the explosion to pass through tubes of different

diameters. In making these experiments in his cottage at the West

Moor, Nicholas Wood and George's son Robert usually acted as his

assistants, and sometimes the gentlemen of the neighbourhood—among

others, William Brandling and Matthew Bell, who were interested in

coal-mining—attended as spectators. One who was present on such an

occasion remembers that, when an experiment was about to be

performed, and all was ready, George called to Mr. Wood, who worked

the stop-cocks of the gasometer, "Wise on [turn on] the hydrogen,

Nichol!"

These experiments were not performed without risk, for on one

occasion the experimenting party had nearly blown off the roof of

the cottage. One of these "blows up" was described by Stephenson

himself before the Committee on Accidents in Coal Mines in 1835:

"I made several experiments," said he, "as to the velocity required

in tubes of different diameters, to prevent explosion from

fire-damp. We made the mixture in all proportions of light

carburetted hydrogen with atmospheric air in the receiver, and we

found by the experiments that when a current of the most explosive

mixture that we could make was forced up a tube four tenths of an

inch in diameter, the necessary current was nine inches in a second

to prevent its coming down that tube. These experiments were

repeated several times. We had two or three blows up in making the

experiments, by the flame getting down into the receiver, though we

had a piece of very fine wire-gauze put at the bottom of the pipe,

between the receiver and the pipe through which we were forcing the

current. In one of these experiments I was watching the flame in the

tube, my son was taking the vibrations of the pendulum of the clock,

and Mr. Wood was attending to give me the column of water as I

called for it, to keep the current up to a certain point. As I saw

the flame descending in the tube I called for more water, and Wood

unfortunately turned the cock the wrong way; the current ceased, the

flame went down the tube, and all our implements were blown to

pieces, which at the time we were not very well able to replace."

The explosion of this glass receiver, which had been borrowed from

the stores of the Philosophical Society at Newcastle for the purpose

of making the experiments, caused the greatest possible dismay among

the party, and they dreaded to inform Mr. Turner, the secretary, of

the calamity which had occurred. [p.185] Fortunately, none of the experimenters were injured by the accident.

Stephenson followed up these experiments by others of a similar

kind, with the view of ascertaining whether ordinary flame would

pass through tubes of a small diameter, and with this object he

filed off the barrels of several small keys. Placing these together,

he held them perpendicularly over a strong flame, and ascertained

that it did not pass upward. This was a farther proof to him of the

soundness of the principle on which he had been proceeding.

In order to correct the defect of his first lamp, he accordingly

proceeded to alter it so as to admit the air to the flame by several

tubes of reduced diameter instead of by a single tube. He inferred

that a sufficient quantity of air would thus be introduced into the

lamp for the purposes of combustion, while the smallness of the

apertures would still prevent the explosion passing downward, at the

same time that the "burnt air" (the cause, in his opinion, of the

lamp going out) would be more effectually dislodged. The requisite

alterations were made in the lamp by Mr. Matthews, a tinman in

Newcastle, and it was so altered that the air was admitted by three

small tubes inserted in the bottom, the openings of which were

placed on the outside of the burner, instead of having (as in the

original lamp) the one tube opening directly under the flame.

This second or altered lamp was tried in the Killingworth Pit on the

4th of November, and was found to burn better than the first lamp,

and to be perfectly safe. But, as it did not yet come up entirely to

the inventor's expectations, he proceeded to contrive a third lamp,

in which he proposed to surround the oil vessel with a number of

capillary tubes. Then it struck him that if he cut off the middle of

the tubes, or made holes in metal plates, placed at a distance from

each other equal to the length of the tubes, the air would get in

better, and the effect in preventing the communication of explosion

would be the same.

He was encouraged to persevere in the completion of his safety-lamp

by the occurrence of several fatal accidents about this time in the

Killingworth Pit. On the 9th of November a boy was killed by a blast

in the A pit, at the very place where Stephenson had made the

experiments with his first lamp; and, when told of the accident, he

observed that if the boy had been provided with his lamp, his life

would have been saved. On the 20th of November he went over to

Newcastle to order his third lamp from Mr. Watson, a plumber in that

town. Mr. Watson referred him to his clerk, Henry Smith, whom

Stephenson invited to join him at a neighbouring public house, where

they might quietly talk over the matter, and finally settle the plan

of the new lamp. They adjourned to the "Newcastle Arms," near the

present High-Level Bridge, where they had some ale, and a design of

the lamp was drawn in pencil upon a half-sheet of foolscap, with a

rough specification subjoined. The sketch, when shown to us by

Robert Stephenson some years since, still bore the marks of the ale. It was a very rude design, but sufficient to work from. It was

immediately placed in the hands of the workmen, finished in the

course of a few days, and experimentally tested in the Killingworth

Pit like the previous lamps on the 30th of November, by which date

neither Stephenson nor Wood had heard of Sir Humphry Davy's

experiments, nor of the lamp which that gentleman proposed to

construct.

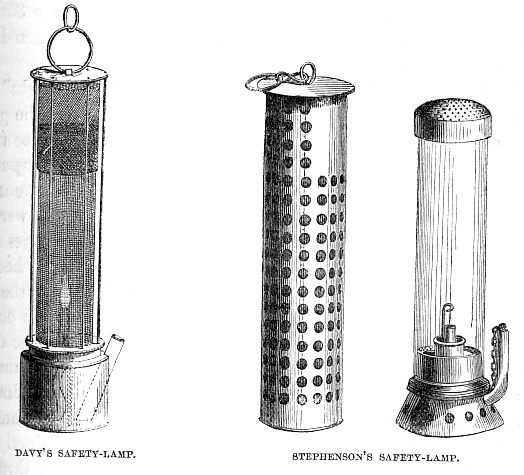

An angry controversy afterward took place as to the respective

merits of George Stephenson and Sir Humphry Davy in respect of the

invention of the Safety-lamp. A committee was formed on both sides,

and the facts were stated in various ways. It is perfectly clear,

however, that Stephenson had ascertained the fact that flame

will not pass through tubes of a certain diameter—the principle on

which the safety-lamp is constructed—before Sir Humphry Davy had

formed any definite idea on the subject, or invented the model lamp

afterward exhibited by him before the Royal Society. Stephenson had

actually constructed a lamp on such a principle, and proved its

safety, before Sir Humphry had communicated his views on the subject

to any person; and by the time that the first public intimation had

been given of his discovery, Stephenson's second lamp had been

constructed and tested in like manner in the Killingworth Pit. The

first was tried on the 21st of October, 1815; the second

was tried on the 4th of November; but it was not until the 9th of

November that Sir Humphry Davy presented his first lamp to the

public. And by the 30th of the same month, as we have seen,

Stephenson had constructed and tested his third safety-lamp.

|

|

|

|

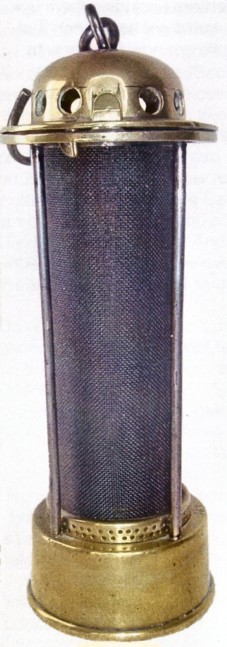

Davy lamp,

made by Evan Thomas of Aberdare,

South Wales, between 1850 and 1860. |

Stephenson lamp - later model,

mid 19th century. |

|

Ed.—photographs by courtesy of David Shaw,

who informs me that similar Davy lamp

models to that shown were sold by

Evan Thomas in a Bill of Sale in 1857 for

5/6d each. |

Stephenson's theory of the "burnt air'' and the "draught" was no

doubt wrong, but his lamp was right, and that was the great fact

which mainly concerned him. Torricelli did not know the rationale of

his tube, nor Otto von Guericke that of his air-pump; yet no one

thinks of denying them the merit of their inventions on that

account. The discoveries of Volta and Galvani were in like manner

independent of theory; the greatest discoveries consisting in

bringing to light certain grand facts, on which theories are

afterward framed. Our inventor had been pursuing the Baconian

method, though he did not think of that; his sole object being to

invent a safe lamp, which he knew could only be done through the

process of repeated experiment. Hence his numerous experiments on